- Home

- >

- News & Resources

- >

- Our Blog

- >

- Basic parameters of injection molding machine

Basic parameters of injection molding machine

The basic parameters of the injection molding machine can better reflect the size of the injection molded product, the function of the injection molding machine, and the evaluation of the type of the material to be processed, the grade range and the quality of the product. It is the design, manufacture, selection and use of the injection molding machine. in accordance with.

1, injection volume - the maximum injection volume that can be achieved by the injection molding system when the injection screw or plunger is used for one maximum injection stroke under air injection conditions.

This parameter reflects the processing capability of the injection molding machine to a certain extent, which indicates the maximum quality of the plastic injection molding machine. It is an important parameter of the injection molding machine. There are generally two representations of the injection quantity, one is based on PS ( The density ρ = 1.05 g/cm3) is expressed by the mass (g) of the injected melt, and the other is expressed by the volume (cm3) of the injected melt.

By definition, the theoretical value of the maximum injection capacity that can be injected at one time by the injection screw is the product of the maximum projected area of the screw head in its vertical and axial directions and the stroke of the injection screw. QL =π/4 D2 S

The injection molding machine can't reach the theoretical value during the working process, because the density of the plastic changes with the change of temperature and pressure. Therefore, the injection capacity needs to be properly corrected. The corrected injection capacity is Q=αQL =π /4 D2 Sα, α - injection coefficient, generally 0.7∽0.9,

Processing plastic products on the injection molding machine, the quality of the general product and the total amount of the casting system should not exceed 25% ∽ 70% of the injection molding machine injection volume.

2, injection pressure - the force of the screw or plunger end face on the unit area of the melt, the size of the injection pressure and the structure of the injection molding machine, flow resistance, product shape, plastic properties, plasticization, plasticizing temperature, mold structure The mold temperature is related to the accuracy requirements of the product. In actual production, the injection pressure can be adjusted within the allowable range of the machine. The injection pressure should be selected according to the actual situation. The general injection pressure selection range is as follows.

A, the material has good fluidity, the shape of the product is simple, the arm thickness is large, and the general injection pressure is less than 340 ∽ 540 Kgf/cm 2 . Suitable for processing LDPE, PA and other materials.

B. The material melt viscosity is low, the product precision is general, and the injection pressure is 680∽980Kgf/cm2. Suitable for processing materials such as PS and HDPE.

C, the material melt viscosity is medium or high, the product precision is required, the shape is complex, and the injection pressure is 980∽1370Kgf/cm2. Suitable for processing of PP, PC and other materials.

D. The material has high melt viscosity, the product is thin wall, long process, high precision and complex shape, and the injection pressure is 1370∽1670Kgf/cm2. Suitable for processing nylon, polysulfone, polyphenylene ether and other materials.

E. When processing high-quality precision micro-products, the injection pressure can reach 2260∽2450Kgf/cm2 or more.

In order to meet the processing requirements of injection molding precision products or complex structural shapes and engineering structural parts, the processing capacity of injection molding machines is enhanced, the molding cycle is shortened, the product quality is improved, and the injection pressure is increased.

3. Injection time (injection speed) - the melt begins to cool after passing through the nozzle. In order to inject the melt into the mold cavity in time to obtain a dense and uniform product with high precision, the melt must be filled into the cavity in a short time. In addition to having sufficient injection pressure, there must be a certain flow rate, which is used to indicate the parameters of the melt filling speed.

4, plasticizing capacity - the amount of material that can be plasticized in a unit of time, the general plasticizing capacity of the screw is related to the screw speed, drive power, screw structure, material properties and so on. The plasticizing device of the injection molding machine should be able to provide a sufficient amount of plasticized and uniform melt within the specified time. The plasticizing capacity should be coordinated with the entire molding cycle of the injection molding machine. The theoretical plasticizing capacity of the general injection molding machine is greater than the actual one. About 20% of the demand.

Basic parameters of the clamping system

1. Clamping force—The maximum clamping force applied by the clamping mechanism to the mold. Under this force, the mold should not be topped. It reflects the size of the product that can be processed by the injection molding machine to a certain extent. It is an important parameter. Our company adopts the maximum clamping force as the specification of the injection molding machine. Before the melt is injected into the cavity at a certain speed and pressure, it is necessary to overcome the resistance flowing through the nozzle, the runner, the gate, etc., and some of the pressure is lost, but the melt also has a relatively high pressure when filling the mold. The mold pressure in the cavity, referred to as the cavity pressure, the mold cavity pressure formed during the injection molding will force the mold to open, in order to ensure that the product molding fully meets the accuracy requirements, the clamping system must have sufficient clamping Force to lock the mold.

In the injection molding, in order to make the mold not open by the cavity pressure formed by the cavity pressure, the clamping force F=KPcpA (F clamping force Kg; K safety factor, generally takes 1∽2; the average in the Pcp cavity Pressure Kgf/cm2; the maximum projected area of the A product and the casting system on the mold parting surface cm2.) The average pressure of the Ccp cavity is a relatively difficult value, which is subject to injection pressure, molding process conditions, material properties, mold structure. , nozzle and runner form, mold temperature, product shape and accuracy requirements and other factors.

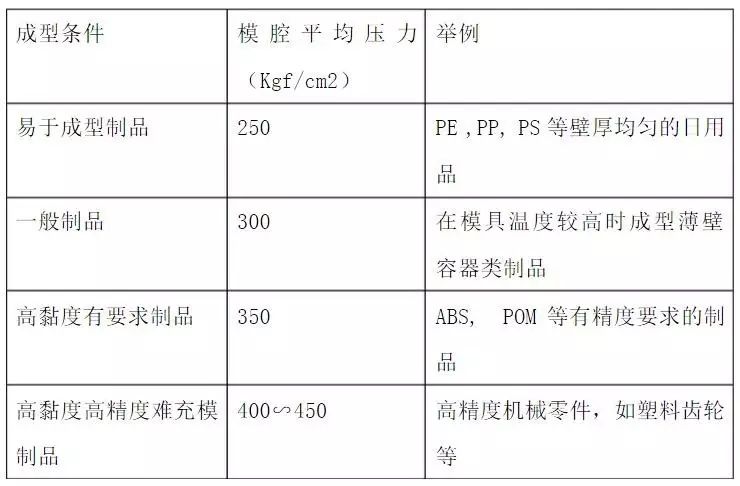

The average cavity pressure can be selected according to Table 2-1.

Table 2-1 Relationship between the average pressure of the cavity and the molded product

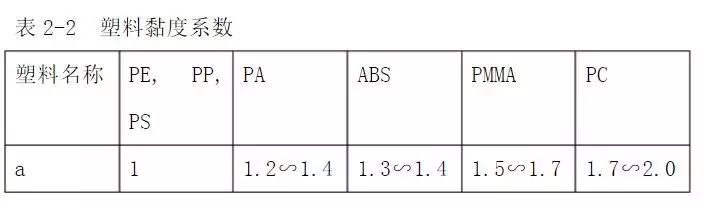

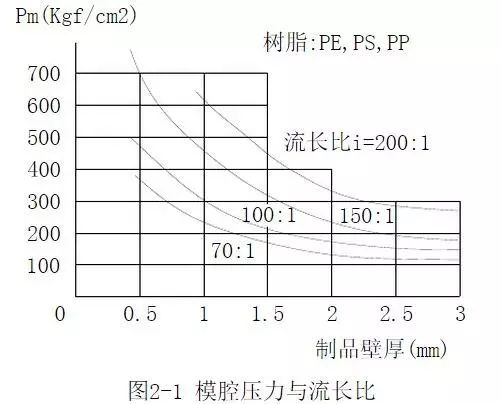

According to Table 2-1, the average pressure of the cavity is selected. The result is coarse. In most cases, the available flow length ratio (i) (the ratio of the melt flow through the gate to the extreme edge of the product and the wall thickness of the product) is reflected. The flow path resistance is expressed by the viscosity coefficient a. The average pressure of the cavity is determined by a look-up (table) calculation.

Pcp= aPm (a viscosity coefficient of plastic; Pm is the cavity pressure value detected by Figure 2-1 according to the flow length ratio)

The selection of the clamping force is very important. If the clamping force of the injection molding machine is not enough, it is easy to make the product fly edge during molding, and the thin-walled product cannot be formed. If the clamping force is too large, it is easy to crush the mold and the internal stress of the product. Increasing and causing unnecessary waste, in recent years, due to improved efficiency of the plasticizing mechanism, improved clamping mechanism, improved injection speed and process control, the clamping force of the injection molding machine has been significantly reduced.

2. The basic size of the clamping system - directly related to the range of products that can be processed and the installation and positioning of the mold, including: template size, tie rod spacing, maximum opening distance between templates, moving template stroke, mold thickness, adjustment Die stroke.

Template size and tie rod spacing - the main parameters of the mold installation area, the size of the mold determines the length and width of the mold, it should be able to install the mold of the general product without the injection molding quality of the injection molding machine, the template area is about the maximum molding of the injection molding machine The area is 4∽10 times, and the mold can be mounted on the template by conventional methods. It can be said that the template size limits the maximum molding area of the injection molding machine, and the distance between the rods limits the size of the mold.