- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- PPR Pipe Fitting Making Injection Molding Machine

- >

- SHE230 PPR Pipe Fitting Making Injection Molding Machine

SHE230 PPR Pipe Fitting Making Injection Molding Machine

Series :PPR Pipe Fitting Injection Molding Machine

Brand :SANSHUN

Model :SHE230PPR

Applications :PPR Pipe Fitting Manufacturing

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Sanshun Machinery offers Special series of Injection Molding Machines for PPR Pipe Fittings making. polypropylene random copolymer (PPR) is a versatile thermoplastic material that is used in the production of hundreds of products.Specially designed for PPR Material, Bi-alloy Screw & Barrel. Stabilized temperature increasing rate from charging. Highly efficient plasticizing rate and stable injection molding. Product quality is excellent. Specially designed for hard PPR mold, convenient to mold installation. Reduce customer cost, increasing the safety of the operator. Standard with fan and wind cover, make sure small material temperature deviation.

Advantages

Heat Transfer systems, Rear & Front Gate Extension, Specially Designed Screw for PPR Processing, Nitride Screw & Barrel, Seal at Screw End, Blowers on Barrel Zones, Extra Heating Zones, stable weight consistency.

Technical Parameters

| MODEL | SHE230PPR | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 50 | 52 |

| Shot size(theoretical) | Cm³ | 608 | 658 |

| Shot weight | g | 546 | 592 |

| Injection pressure | Mpa | 184 | 170 |

| Injection rate | g/s | 160 | 176 |

| Screw L/D ratio | L/D | 22.8 | 21.9 |

| Screw speed | r.p.m | 0-180 | |

| Nozzle Diameter | Srmm | 20 | |

| CLAMPING UNIT | |||

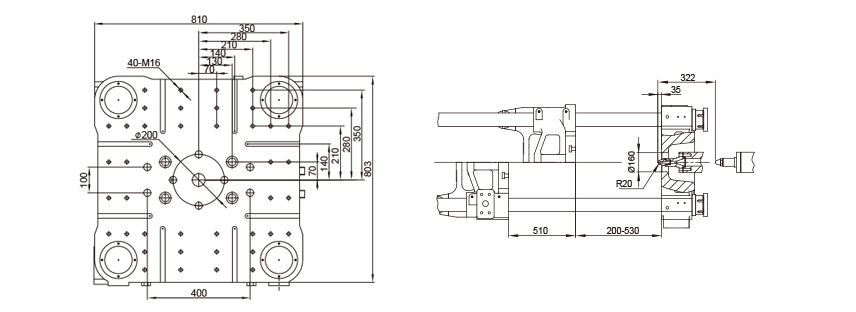

| Clamp tonnage | KN | 2300 | |

| Toggle stroke | mm | 510 | |

| Mould Thickness | mm | 200-530 | |

| Space between tie-bars | mm | 535X533 | |

| Ejector stroke | mm | 155 | |

| Ejector tonnage | KN | 70 | |

| Ejector number | Piece | 9 | |

| Hole Diameter | mm | 160 | |

| OTHERS | |||

| Heat power | KW | 13.7 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 18.5 | |

| Valve Size | mm | 16 | |

| Machine dimension | m | 5.8X1.8X2.0 | |

| Machine weight | t | 6.9 | |

| Oil tank capacity | L | 300 | |

Platen Dimensions

Advantages & Features

.Injection device control position.

.Hard-Chrome Plated High-Tensile Steel Tie-Bars with Stress-Relieve-Design.

.Mechanical, electrical, hydraulic triple chain security protection ( large, medium machine).

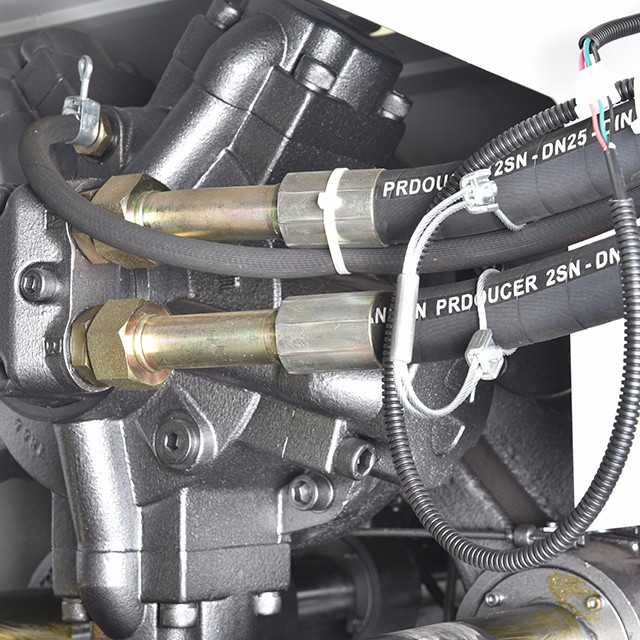

.Double cylinder balanced injection unit.

.Nitride Hardened Screw and Barrel for wear resistance and long life.

.High Torque Hydraulic motor for driven plasticizing Screw Counter.

.Modular injection unit design offering a wide choice for shot weights.

.Precise Screw System with optimized design.

.High-efficiency oil filter device to extend the normal life of the hydraulic oil.

.Hopper Sliding Arrangement for material removal.

.PID temperature control with a high precision electronic ruler.

.Robust & Rugged 5 points toggle clamp with large mould opening stroke.

.High Wear Resistance & High Strength Characters Gear Nut (Tie bar Nut) gives Rigid & Positive Clamping force.

.Abnormal errors alarm function with motor safety protection device.

.Low-pressure mold protection device.

.Progressive Type auto grease lubrication system.

.Heavy-duty toggle design give trouble free precise clamping force for long period.

.High precision suction filter.

.High strength mould platen.

.Anti-vibrating pads with stronger dampening.

.Linear transducer controls Clamping, Injection, and Ejection.

.Shaking ejector for multi-cavity mold.

.Machine motor stop whiling rear gates opening.

.Hydraulic tank low oil level alarming.

.Multi-stage injection speed, refilling speed and the pressure setting.

.High-performance and Large colour LCD display screen.

.PID Temperature Controller for Accurate Control.