- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- Bakelite Injection Molding Machine

- >

- SHE258B Bakelite Injection Molding Machine

SHE258B Bakelite Injection Molding Machine

Series :Bakelite Injection Molding Machine

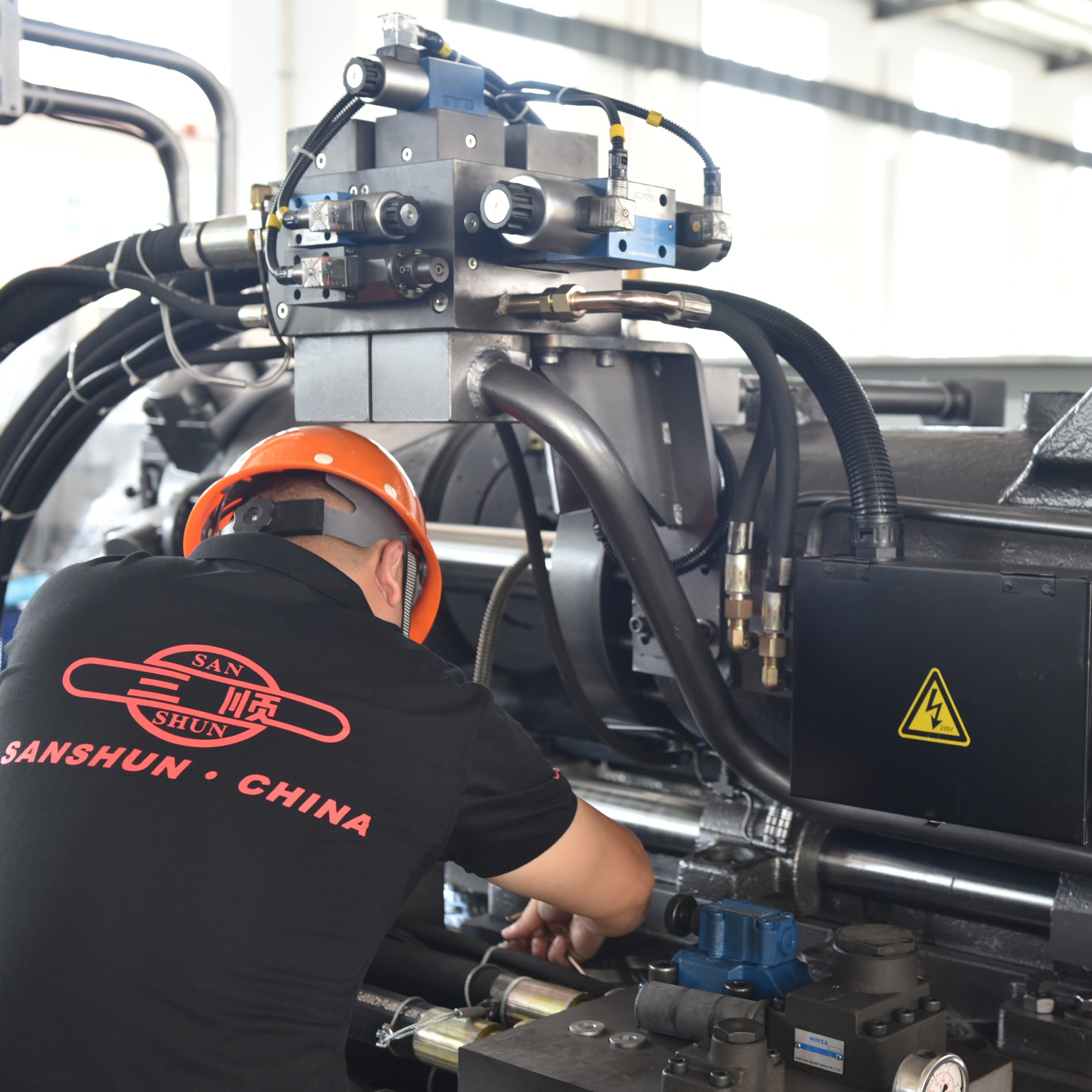

Brand :SANSHUN

Model :SHE258B

Applications : For making bakelite

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Sanshun Machinery manufacturing special Injection molding machines for Bakelite products. Bakelite has a number of important properties. It can be molded very quickly, decreasing production time. Moldings are smooth, retain their shape and are resistant to heat, scratches, and destructive solvents. It is also resistant to electricity and prized for its low conductivity. It is not flexible. These characteristics made Bakelite particularly suitable as a molding compound. For Bakelite injection molding, the barrel temperature is set to 70-90'C to heat (with screw shear) the raw materials flowing. The screw is only for compressing and delivering the material into the mold, without melting it. Mold is heated to a temperature (180'C, for instance) to cure the raw materials

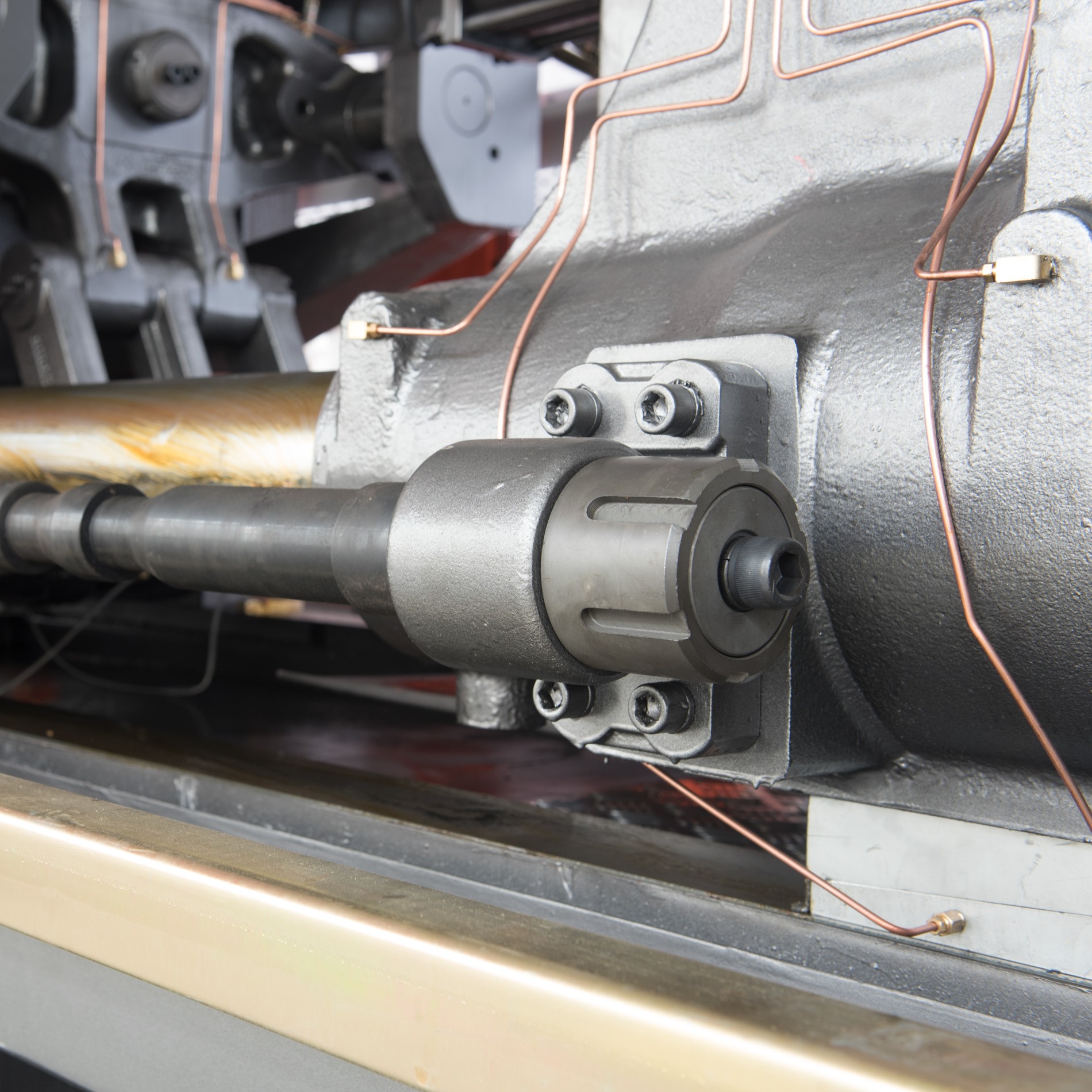

Screw configuration - The compression ratio of the screw for bakelite is 1:1 whereas for thermoplastics it's about 1:3-1:4.5

Process - Molding of thermoplastics involve melting whereas in the molding of bakelite only the fusing takes place between particles and no melting is involved.

Advantages

Specially designed Screw & Barrel, High Efficiency, Automatic Mould adjustment, Energy Saving, Easy processing operations, Less production time.

Technical Parameters

| MODEL | SHE258B | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 50 | 52 |

| Shot size(theoretical) | Cm³ | 610 | 660 |

| Shot weight | g | 730 | 790 |

| Injection pressure | Mpa | 221 | 204 |

| Injection rate | g/s | 171 | 185 |

| Screw L/D ratio | L/D | 16 | 15.3 |

| Screw speed | r.p.m | 0-180 | |

| Nozzle Diameter | Srmm | 20 | |

| CLAMPING UNIT | |||

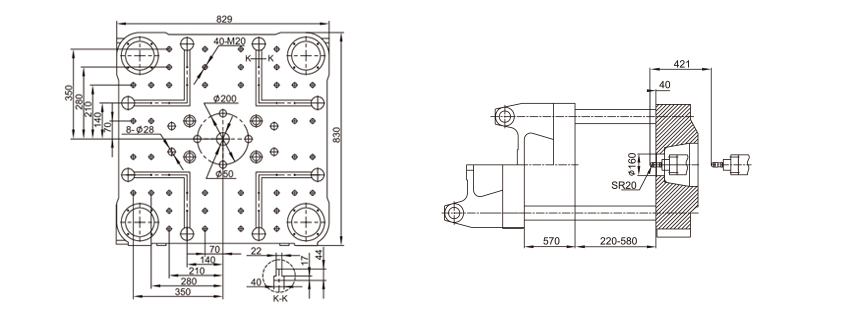

| Clamp tonnage | KN | 2580 | |

| Toggle stroke | mm | 570 | |

| Mould Thickness | mm | 220-580 | |

| Space between tie-bars | mm | 580x580 | |

| Ejector stroke | mm | 160 | |

| Ejector tonnage | KN | 70 | |

| Ejector number | Piece | 9 | |

| Hole Diameter | mm | 160 | |

| OTHERS | |||

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 25 | |

| Machine dimension | m | 6.3X1.8X2.0 | |

| Machine weight | t | 8 | |

| Oil tank capacity | L | 350 | |

Platen Dimensions

Advantages & Features

|